A picture’s worth…

A peaceful sunset to celebrate the builder-now-driver’s first solo manuevers, docking Ravenswing back at CharlieJ’s after a big day getting the mast stepped at Napa Valley Marina. We again had a nice big crew starting at 8am, and by 3:30 the stick was upright and everyone else rolled home. I had a couple of quiet hours to finish standing rigging install chores, all the while fretting the wind pinning the boat up against the reeds and muddy bank beneath the crane. (How would we motor out of this tricky spot???)

A peaceful sunset to celebrate the builder-now-driver’s first solo manuevers, docking Ravenswing back at CharlieJ’s after a big day getting the mast stepped at Napa Valley Marina. We again had a nice big crew starting at 8am, and by 3:30 the stick was upright and everyone else rolled home. I had a couple of quiet hours to finish standing rigging install chores, all the while fretting the wind pinning the boat up against the reeds and muddy bank beneath the crane. (How would we motor out of this tricky spot???)

But back to the top. The daggerboard “sticky wicket” emergency shop work led to an anxious Sunday re-install.

If that’s hard to see, it’s because it’s ALL THE WAY DOWN in this shop. Yea, the mast step can go back in over this trunk. This board is big. It floats, so moving it through most of its travel is pretty easy by hand, but the last foot or so up or down needs a winch. If we’re needing to pull it up fast because of an obstacle, simply freeing the down line will pop the board up three feet in a few seconds.

If that’s hard to see, it’s because it’s ALL THE WAY DOWN in this shop. Yea, the mast step can go back in over this trunk. This board is big. It floats, so moving it through most of its travel is pretty easy by hand, but the last foot or so up or down needs a winch. If we’re needing to pull it up fast because of an obstacle, simply freeing the down line will pop the board up three feet in a few seconds.

With the dagger solved, attention turned to prepping the mast. ‘Dressing’ took about 3 hours by RickW, RickH and Dean. Holding the mast upright is highly dependent on one huge shackle on the front face near the top. Here’s the pin coming in from the port side into the Jesus shackle. (Yes we pray this thing never gives way)

And two years of making sure the halyard messenger lines didn’t get trashed in the shop or transport. So happy when all five halyards popped out the bottom.

Now ready for the crane. We had to move about 500 yards to a stable crane parking pad with only the mud bank and reeds for the boat. (Sorry these are in backwards order)

Now ready for the crane. We had to move about 500 yards to a stable crane parking pad with only the mud bank and reeds for the boat. (Sorry these are in backwards order)

The straps for walking it across the yard very different from the vertical lift, and we had transition time while the crane sat at the water and I went to fetch the boat. Standing it up was painless, especially due to the skill and equipment of the Napa Valley guys.

The straps for walking it across the yard very different from the vertical lift, and we had transition time while the crane sat at the water and I went to fetch the boat. Standing it up was painless, especially due to the skill and equipment of the Napa Valley guys.

Yard manager Mike had to stand there 15 mins holding the mast in the rotator ball while we struggled with lacing the 1/4″ spectra through the lacing eyes. But a couple of small trims, cussing and “just push harder!” Got it done.

Yard manager Mike had to stand there 15 mins holding the mast in the rotator ball while we struggled with lacing the 1/4″ spectra through the lacing eyes. But a couple of small trims, cussing and “just push harder!” Got it done.

It’s amazing seeing a big mast rotating freely in the breeze – so foreign to the monolithic columns of seeming sturdiness that most associate with sailboat masts. A wednesday evening sail aboard Mile Leneman’s big fast cat Minette prepared me for today.

All shrouds and stays were set, so I had to call for the crane release. Now or never, don’t be shy about it…

Step back a hundred yards and she looks like an F31.

Step back a hundred yards and she looks like an F31.

Sunday night I had trouble motoring in close quarters. We need to sort out motor steering. This evening was a shot at redemption, and it worked. Holdin the motor makeshift turnin lines and respecting the transitions from forward to backwards made this go much better.

A word to the other first time builders:

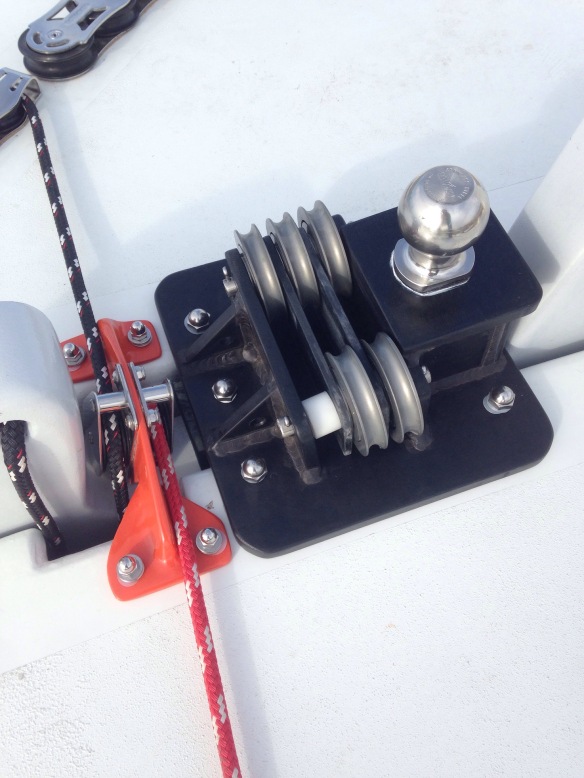

That’s not a deck hardware photo; that’s the result of countless nights and weekends in the shop working one part at a time. The final install where this stuff begins to fit together is so worth it! Keep going.

That’s not a deck hardware photo; that’s the result of countless nights and weekends in the shop working one part at a time. The final install where this stuff begins to fit together is so worth it! Keep going.

A few more glam shots here, then it’s back to the shop evenings this week for ladders, hatch boards, pulpit, etc.

And now we’re official, courtesy of the USCoastGuard. Ravenswing got her number today so we’ll get busy making an ID plate / board to mount near the chart table. That was quick paperwork turning by the govt!

And now we’re official, courtesy of the USCoastGuard. Ravenswing got her number today so we’ll get busy making an ID plate / board to mount near the chart table. That was quick paperwork turning by the govt!

</a

</a